Ready to invest in a cutting machine? This definitive guide helps you choose the perfect fit from Flatbed Digital Cutters, Roll-to-Roll Vinyl Plotters, CO₂/Fiber Laser Cutters, or CNC Cutting Machine. We break down the budgets (in RM), site-prep, and ROI math you need to launch your new automated cutting system today.

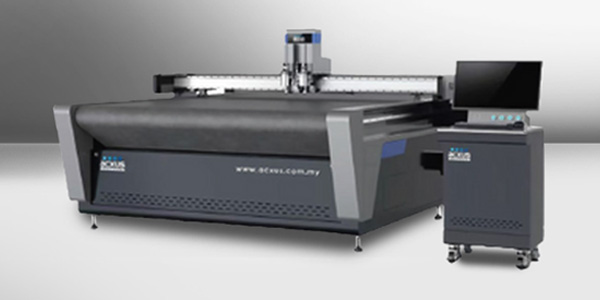

1) Flatbed Digital Cutting Machine (for Boards, Packaging & Foam)

Packaging mockups, short-run production, POP displays, foam inserts, corrugated boards, perfect for Digital Die Cutting.

**Image:** The RUK MKC L-Series Flatbed, specialised for packaging, corrugated boards, and foam.

Key Capabilities

- Interchangeable tool heads: oscillating/drag knife, creasing wheel, V-cut, kiss-cut, optional light router module

- Camera registration (i-cut style) for perfect print-to-cut alignment

- Vacuum zones for material hold-down; optional conveyor/auto-feeder for high-volume production

Indicative Budgets (RM)

- Entry (A1/A0 bench-top): RM40k–90k

- Mid (1.6–2.5 m, e.g., RUK ACM-1625): RM120k–250k

- Industrial (3.2 m+, conveyor): RM260k–480k+

Malaysia Checks

- Power: Most mid/large tables are single-phase 230V, but router modules draw more. Confirm with your electrician.

- Vacuum Noise & Space: Plan the pump’s placement for airflow and to manage noise levels.

- Consumables: Check local stock and pricing for blades, creasing wheels, and cutting mats.

- Software: Ensure your RIP/print workflow is compatible with the cutter’s registration software.

Who Shouldn’t Buy This?

If 90% of your work is vinyl from rolls, a roll-to-roll plotter is much faster and more cost-effective.

2) Roll-to-Roll Cutting Plotters (for Vinyl, Stickers & HTV)

The workhorse for sign shops, apparel (Heat Transfer Vinyl), die-cut labels/stickers, and vehicle graphics.

Key Capabilities

- Optical registration (e.g., OPOS, ARMS) for accurate print-and-cut jobs

- High downforce & speed for thicker films (like sandblast) and higher throughput

- Widths from 24″ to 64″ to match your large-format printer

Indicative Budgets (RM)

- Entry 24–28″: RM2k–6k

- Pro 48–64″ (e.g., Mimaki CG-SRIII): RM7k–15k

- Sheet/label auto-feed systems: RM8k–25k

What to Check

- Media Handling: Ask for a demo of tracking accuracy on a long run (e.g., 3-5 meters).

- Downforce Range: If you cut reflective or sandblast films, you need higher g-force.

- Blades & Holders: Check availability and cost in Malaysia.

- Warranty & Calibration Support: Who provides local support?

Who Shouldn’t Buy This?

If you mainly need to finish rigid boards (foam, corrugated, acrylic), you must get a flatbed cutter.

3) CO₂ & Fiber Laser Cutting Machine (for Acrylic, Wood & Metal)

CO₂ Lasers: Best for acrylic (creates a polished edge), wood, leather, paper, and engraving.

Fiber Lasers: Specifically for metal cutting/marking (stainless steel, carbon steel, some aluminium).

Key Differences

- CO₂ Laser: Cuts non-metals and provides beautiful, fine engraving.

- Fiber Laser: Cuts and marks metals. Involves higher cost and critical safety protocols.

Indicative Budgets (RM)

- Desktop/Entry CO₂ (600×900 mm): RM6k–30k

- Industrial CO₂ (1300×900 to 2000×3000): RM35k–120k

- Fiber Laser Metal Tables (1kW+): RM200k–700k+

Malaysia Checks (Critical)

- Fumes & Extraction: You MUST plan for ducting or industrial filter units. This is a safety and production requirement.

- Materials Safety: Not all plastics are safe to laser (e.g., PVC releases toxic gas).

- Spares: Check replacement cost & local stock for the laser tube (CO₂) or fiber source, lenses, and mirrors.

- Safety: Ensure the machine has safety interlocks, and budget for proper eyewear and training.

Who Shouldn’t Buy This?

For deep 3D carving in wood or large-format panel processing, a CNC router is a better fit.

4) CNC Routers Cutting Machine (for Wood, ACP & 3D Carving)

Best for deep cutting, profiling, 3D carving/pocketing, jigs/fixtures, furniture components, and Aluminum Composite Panel (ACP) signboards.

**Image:** Our AC1325 CNC Router featuring the CCD Camera system for precise print-to-cut registration.

Key Capabilities

- Spindle Power (2.2kW to 9kW+); determines cutting force and speed.

- Optional ATC (Auto Tool Changer) for multi-bit jobs without stopping.

- Vacuum table with T-slots for workholding; requires a robust dust extraction system.

- Excellent for 2.5D relief carving and precise depth control.

Indicative Budgets (RM)

- Entry (~1300×2500 mm, 2.2–4 kW): RM30k–80k

- Pro/ATC (4–9 kW, larger beds): RM90k–220k+

Malaysia Checks

- Power: Many pro models require 3-phase power. Verify your building’s supply with TNB and an electrician first.

- Workholding: A strong vacuum pump is key. Factor in the cost of spoilboards (MDF).

- Bits/Consumables: Check local availability of end mills, V-bits, and surfacing bits.

- Dust Control: Budget for a proper dust extractor and ducting, especially for wood/MDF.

Who Shouldn’t Buy This?

For fine photo engraving or polished acrylic edges, a CO₂ laser gives superior results. For vinyl, a plotter is the only answer.

Calculate Your ROI: Cost vs. Return

Don’t just guess—run the numbers. Use this simple calculator to estimate your payback period.

Static Example:

- Machine Price: RM180,000

- Jobs per month: 60

- Avg. Profit per job: RM180

- Monthly Running Costs (labor, electric, bits): RM1,500

- Calculation: (60 jobs * RM180 profit) – RM1,500 = RM9,300 Net Profit / Month

- Payback: RM180,000 / RM9,300 = 19.4 months

🧮 Your Interactive ROI Calculator

Your Estimated Results:

Monthly Gross Profit (B × C): RM 10,800.00

Monthly Net Profit (Gross – D): RM 9,300.00

Payback Period:19.4 Months

Pre-Installation: Your Site-Prep Checklist

A smooth installation starts with good preparation.

- Power: Confirm voltage (230V/415V), phase (1-phase/3-phase), and have a dedicated breaker and clean earth/grounding.

- Space: Measure doorway clearance, final footprint, and leave 1-meter service space around the machine.

- Ventilation: Plan the laser extraction path. Decide where the noisy vacuum pump (for flatbeds/routers) will go.

- Dust & Waste: Have a dedicated dust extractor (for routers) and a plan for scrap material handling.

- Network/USB: How will the machine get its files? Does it need a network drop or a dedicated PC?

- Safety: Have the correct fire extinguisher (e.g., CO₂ for electronics), PPE/eyewear (lasers), and tested E-stops.

- Training Plan: Who will be trained? Schedule 1-2 full days and start writing your internal SOPs.

- Spares: Get a “starter kit” of essential consumables: blades, bits, nozzles, lenses, belts, filters.

Decision Matrix: Which Cutting Machine is Right for You?

Use this table for a quick comparison.

| Need / Material | Plotter (Roll) | Flatbed Digital | CO₂ Laser | Fiber Laser | CNC Router |

|---|---|---|---|---|---|

| Vinyl/HTV/Labels | ✅ | – | – | – | – |

| Packaging boards/foam | – | ✅✅ | – | – | – |

| Acrylic (polished edge) | – | ⚠️ score only | ✅ | – | ✅ (no polish) |

| Wood engraving | – | – | ✅ | – | ⚠️ carving, not fine engraving |

| Metal cutting | – | – | – | ✅✅ | – |

| Deep pockets/relief | – | – | – | – | ✅✅ |

| Print-to-cut sheets | – | ✅ (camera) | – | – | ⚠️ with camera |

| Print-to-cut rolls | ✅ | – | – | – | – |

Legend: ✅ recommended · ✅✅ ideal · ⚠️ possible with compromises · – not suitable

Still Unsure? Let’s Find Your Fit.

This guide is a start, but the right machine depends on your exact materials, space, and business goals. A 15-minute call can save you RM10,000s.

Our team can help you analyse your workflow, compare running costs, and arrange a live demo (in-person or virtual) on a machine that fits your budget.

Common (and Costly) Mistakes to Avoid

- Buying on bed size alone. The tool heads, registration accuracy, and software are often more important than an extra 10cm of width.

- Underestimating Lifetime Costs. A cheap machine with no local support or expensive, hard-to-find consumables (blades, lenses, bits) will lead to costly downtime. Always ask for a local-stock consumables price list and warranty response times.

- Under-ventilating lasers. Fumes will damage the machine, harm your staff, and stop production. Specify and budget for proper filters/ducting from day one.

- No filtering plan on routers. Poor work holding (clamping or vacuum) is the #1 cause of ruined materials, broken bits, and poor accuracy.

- No operator training budget. Plan for 1-2 full days of dedicated training for your team and write down your SOPs. A powerful machine is useless if no one can operate it safely and efficiently.

Your Questions Answered (Malaysia Context)

Do I need 3-phase power?

It depends. Most CNC routers and larger fiber lasers will require 3-phase (415V). Many flatbeds, CO₂ lasers, and all plotters run on standard single-phase (230V). Always confirm the exact model’s requirements with an electrician.

Can one digital cutting machine do everything?

No. This is the most common misconception. A plotter excels on rolls, a flatbed on sheets, a laser on engraving/polishing, and a router on deep carving. Trying to make one machine do another’s job (like cutting foam on a router) is slow, inefficient, and gives poor results.

How do I size the bed/width?

Match your largest common media size, then add handling space. For plotters, match your printer width (e.g., 54″ printer → 54–64″ plotter). For flatbeds, the most common sheet size is 4ft x 8ft (1220 x 2440 mm).

What after-sales support should I insist on?

Don’t just ask “is there support?” Ask for specifics:

- What is your guaranteed on-site response time (in Klang Valley vs. outstation)?

- Where are your spare parts (blades, belts, tubes, lenses) stocked? In Malaysia or overseas?

- Is on-site training included, and how many days?

- What are the clear preventive maintenance steps I need to follow?

Are there financing options or SME grants?

Yes, as these are major capital expenditures, most suppliers offer financing or leasing options (e.g., 2-5 year plans). Furthermore, many of these machines qualify for Malaysian government initiatives like the SME Digitalisation Grant or other tax incentives (like Capital Allowance) aimed at automation and manufacturing. Ask your supplier for a quote you can use for your application.